Jim Moran got some bad news last October while he was preparing for the Hamilton Wood Type & Printing Museum’s annual conference in Two Rivers, Wisconsin. Moran, who is director of the world’s only museum dedicated to the preservation, study, production, and printing of wood type, was told by his landlord that the museum had six months to find a new home.

The news wasn’t entirely a shock. Moran and his small team had noticed that the building owner, lab equipment manufacturer Thermo Fisher Scientific, had begun downsizing the employees that shared the massive building, which was rapidly deteriorating. The museum, which was founded in 1999, took up 12,000-square-feet (with an additional 25,000 for storage) of the three-block long, 1.3 million-square-foot facility that the Hamilton Manufacturing Company had built, and added to, from 1910 to 1926. The manufacturer had donated free rent, lighting, and heat to the museum, but they were now closing their Two Rivers plant and moving production elsewhere. (MORE AFTER PHOTOS)

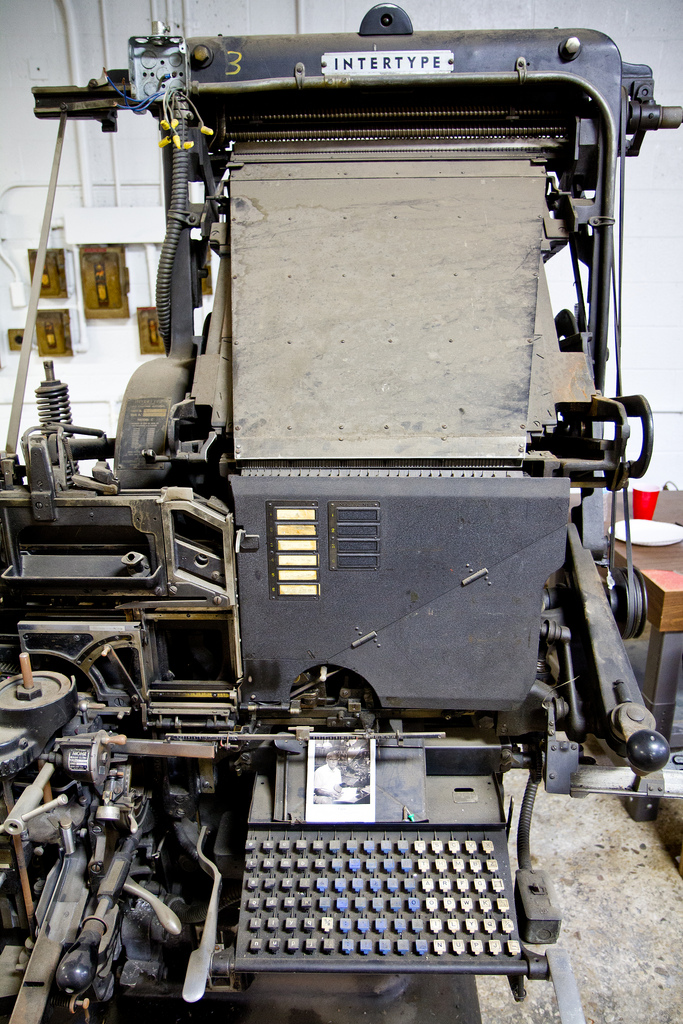

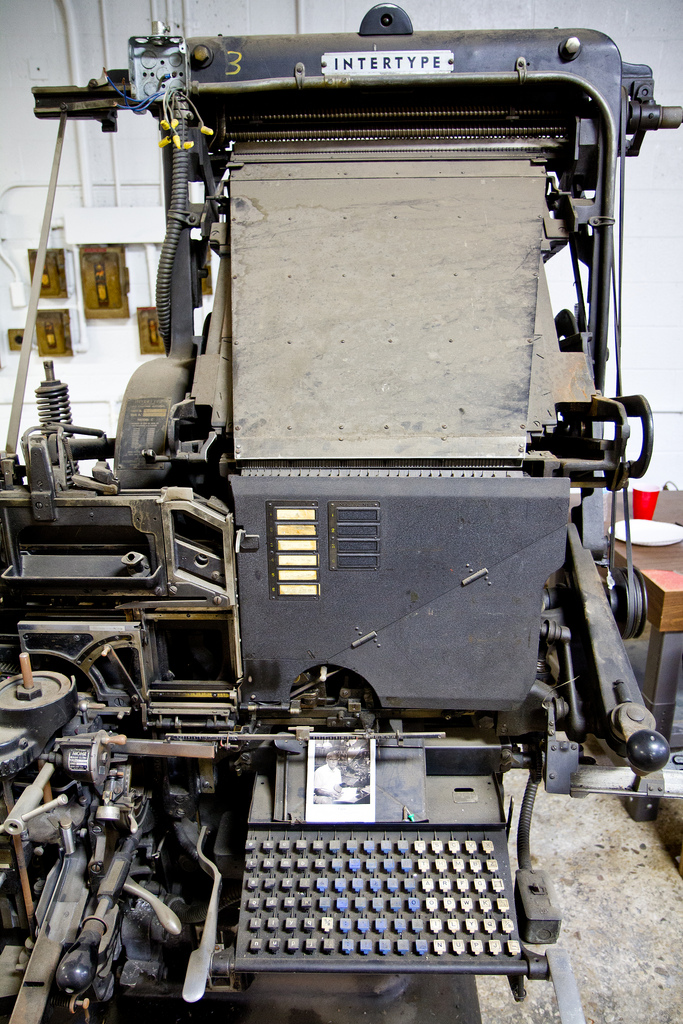

Part of the exhibit in the Hamilton Wood Type Museum in Two Rivers, Wisconsin. © Lester Public Library

Part of the exhibit in the Hamilton Wood Type Museum in Two Rivers, Wisconsin. © Lester Public Library

Part of the exhibit in the Hamilton Wood Type Museum in Two Rivers, Wisconsin. © Lester Public Library

Part of the exhibit in the Hamilton Wood Type Museum in Two Rivers, Wisconsin. © Lester Public Library

Part of the exhibit in the Hamilton Wood Type Museum in Two Rivers, Wisconsin. © Sketchbook B

Part of the exhibit in the Hamilton Wood Type Museum in Two Rivers, Wisconsin. © Sketchbook B

Part of the exhibit in the Hamilton Wood Type Museum in Two Rivers, Wisconsin. © cowofchange

Part of the exhibit in the Hamilton Wood Type Museum in Two Rivers, Wisconsin. © cowofchange

Part of the exhibit in the Hamilton Wood Type Museum in Two Rivers, Wisconsin. © cowofchange

Part of the exhibit in the Hamilton Wood Type Museum in Two Rivers, Wisconsin. © cowofchange

Part of the exhibit in the Hamilton Wood Type Museum in Two Rivers, Wisconsin. © Lester Public Library

Inside the relocated Hamilton Wood Type Museum in Two Rivers, Wisconsin. © Lester Public Library

The exterior of the relocated Hamilton Wood Type Museum in Two Rivers, Wisconsin. © Lester Public Library

The site of the original Hamilton Wood Type Museum in Two Rivers, Wisconsin. © Lester Public Library

The site of the original Hamilton Wood Type Museum in Two Rivers, Wisconsin. © Lester Public Library

The site of the original Hamilton Wood Type Museum in Two Rivers, Wisconsin. © Lester Public Library

Jim Moran, Museum Director, Hamilton Wood Type Museum in Two Rivers, Wisconsin. © Lester Public Library

The site of the original Hamilton Wood Type Museum in Two Rivers, Wisconsin. © Lester Public Library

Moran had to quickly raise the estimated $250,000 needed to pack up and move the world’s largest collection of type, as well as cover the lost income of closing the museum and salaries for the staff. “That really left it to the three of us to devise a way we could raise the money,” says Moran. “Of course, nobody knew if we could do it.”

Through generous donations from companies and individuals, the museum raised the funds it needed to move. It was as late as mid-March when Moran found the museum’s new home: a 85,000 square-foot Mid-Century factory building with a view of Lake Michigan owned by the Formrite Tube Company. While the new building is just 10 blocks from the original site, the logistics of moving the collection, ranging from small bits of type to equipment weighing over a ton, was challenging to say the least. “I had estimated we needed 17 semi loads of equipment, but we moved 26,” says Moran.

The museum enlisted the help of volunteers to help pack up and unpack, but much of the actually loading fell to the staff since they needed to work around the availability of the donated trucks. While Moran’s staff used a labeling and numbering system for every single piece, there was still some disorganization in the unloading process. “You might pack things up, but you don’t remember everything you put in that box,” he says. Despite a broken display case and a little cracking on the wood block bases of some of the equipment pieces, the entire collection was safely relocated by the first week of May.

The move was bittersweet for Moran, who would have preferred to still be in the original factory for historic reasons, but knew it wasn’t the best choice for the museum. “The collection was being compromised in that building,” he says. “A great thing about this building, is that it does not leak.” The fate of the original Hamilton factory is uncertain. “We fear that it is going to be demolished,” says Moran. “We wish it could be saved, but we think there is a really good chance that some of it, if not all of it, will come down.”

While the museum’s current expenses make hiring an architect prohibitive, they hope they might find someone willing to donate consulting time to help them with the new space. Moran plans to reopen the museum by October in time for their annual conference that draws attendees from around the world. “We are feeling good about it,” he says. “We have customers already lined up.”

To learn more about the Hamilton Wood Type & Printing Museum or to make a donation visit http://woodtype.org. The museum’s annual Wayzoose conference will take place November 8th through November 10th in the new building, located at 1816 10th Street, Two Rivers, Wisconsin, 54241. — Rita Catinella Orrell

This article by Rita Catinella Orrell first appeared on Architects + Artisans.